Turnkey refurbishment solutions

Medical Air Technology delivers turnkey refurbishment solutions across the full range of life science facilities – aseptic suites, cleanrooms and containment laboratories.

Aseptic suites:

Including radiopharmacies, stem cell laboratories, cytotoxic pharmacies, gene therapy, total parenteral nutrition (TPN) and in vitro fertilisation (IVF).

Aseptic suites are used for manufacturing medicines such as chemotherapy injectables. The airflow design facilitates cascading pressure, which ensures that the most stringent cleanroom zone has the highest level of pressure, and the least stringent cleanroom zone has the lowest level of pressure, so the flow of contamination is from clean to less clean.

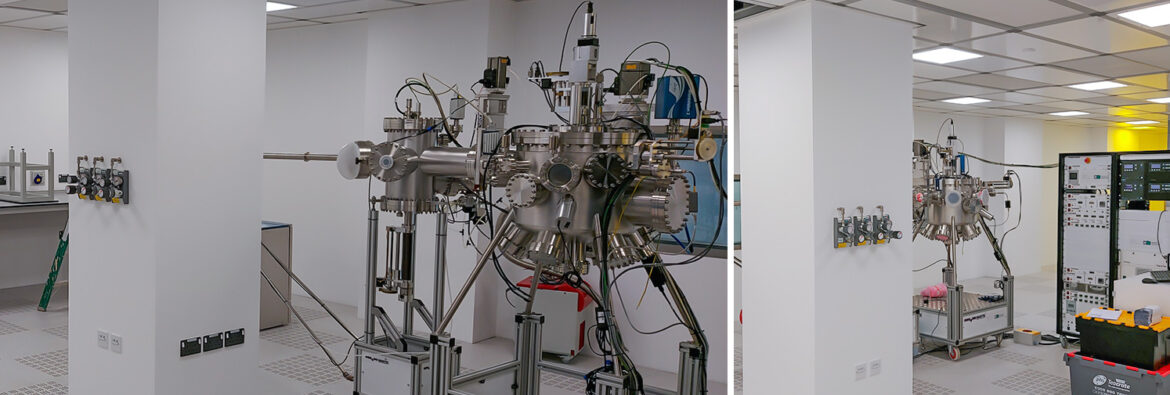

Cleanrooms:

Used in many sectors, such as electronics, research and pharmaceutical manufacturing.

A very prestigious London university brought us in to deliver the complete turnkey design and build of an ISO 6 cleanroom suite. The wide scope of work included a terminal HEPA filtered air supply air ducting from a packaged dedicated AHU, a chemical extract duct system, full system control, custom-built chemical ISO Class 5 laminar flow wet benches and laminar downflow hoods, laboratory furniture, chemical-resistant sink, polypropylene benching, shelving and cupboards, interlocked fire-rated GRP laboratory doors and access control, laboratory lighting, windows and everything else needed to create the perfect environment for preparing complex natural samples for analysis.

Containment laboratories:

Used in many fields, for example microbiology, forensic science, tropical disease research, immunology and vaccinology, biotechnology and veterinary medicine.

A recent turnkey refurbishment project delivered by Medical Air Technology for a university featured high specification CL2 and CL3 laboratory suites, accessed via a lobby and a central anteroom. The design allowed for an increased progression of negative pressure, which was essential to create a safe environment to meet the client’s research needs. MAT also installed furniture including class I, II and III microbiological safety cabinets and autoclaves.

In addition, all work was completed to SR4 standards. This refers to the security rating classification as required by Loss Prevention Certification Board Loss Prevention Standard 1175 (LPCB LPS 1175).

Life science turnkey refurbishment solutions

- London School of Hygiene and Tropical Medicine, London

- University of Leeds, Leeds

- Imperial College, London

- Aberystwyth University, Wales

- New Cross Hospital, West Midlands

- Royal Free Hospital, Pears Building, London