Expertise

NHS, private healthcare providers, universities, research and pharmaceutical manufacturing facilities

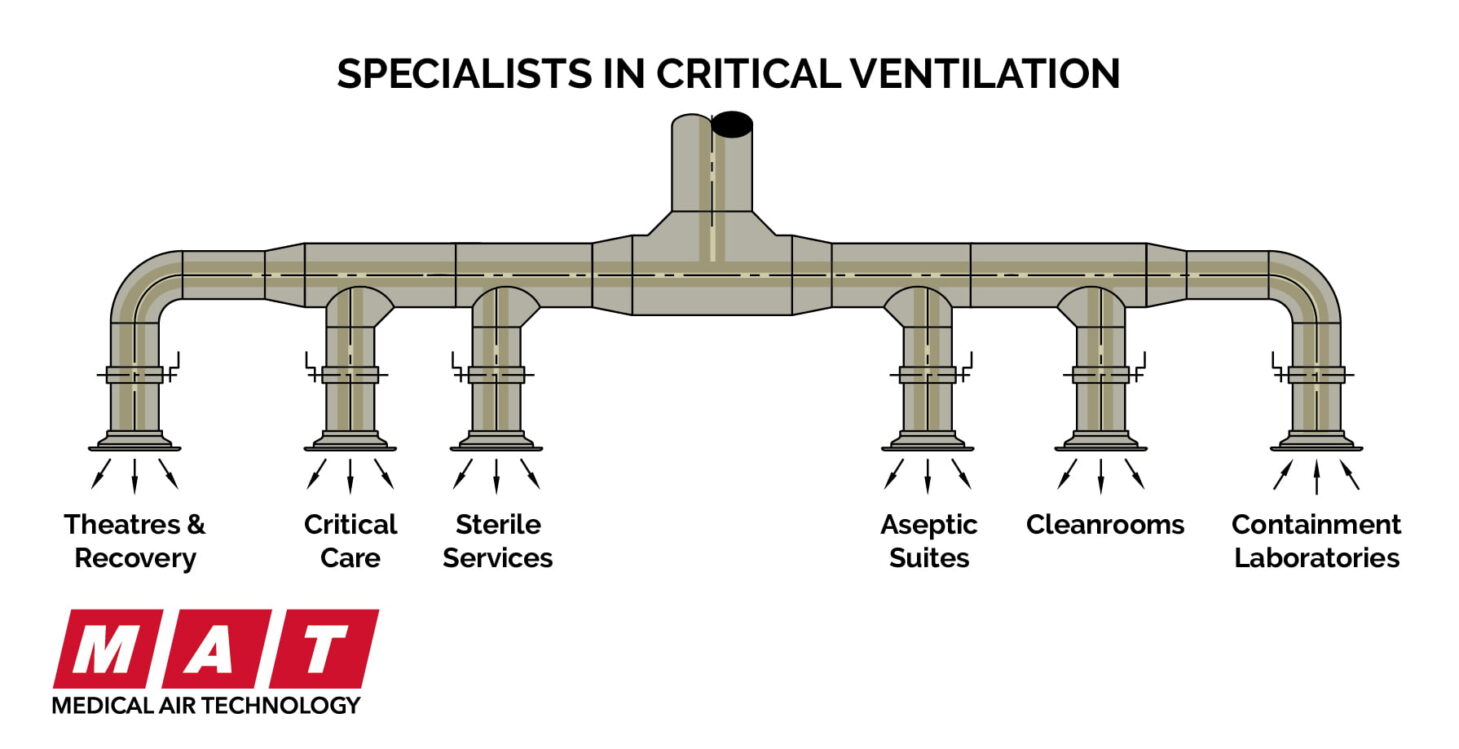

We deliver design-and-build ‘box-in-a-box’ critical ventilation solutions that encompass key areas within the general plan of your building and are suitable for both new build and refurbishment projects.

Our facilities management division MAT FM offers service, maintenance and validation of all the critical ventilation systems we install.

Operating theatres and recovery

Operating theatres rely on clean air systems to reduce airborne contaminants and maintain environmental conditions for staff.

The operating theatre suite also contains other key areas for perioperative practice, such as an anaesthetic room, preparation room, scrub, dirty utility and first stage post-anaesthesia recovery.

Critical care

Critical care areas need dedicated ventilation to ensure the safest conditions for vulnerable patients with severe or life-threatening illnesses and injuries.

Examples include isolation rooms (positive and negative), high dependency units (HDU), newborn and paediatric intensive care units (NICU, SCBU and PICU), critical care units (CCU), intensive therapy units (ITU) and intensive care units (ICU).

Sterile services

Surgical instruments are washed, sterilised and packed in the sterile services area before being taken to the theatre. Critical ventilation is key in ensuring that they are kept as clean as possible as they pass through the process.

This area is known variously as the central sterile services department (CSSD), theatre sterile services unit (TSSU) or hospital sterilisation and decontamination unit (HSDU).

Aseptic suites

Aseptic suites maintain positive pressure via specialist HVAC and room design.

Radiopharmacies, stem cell laboratories, cytotoxic pharmacies, gene therapy, total parenteral nutrition (TPN) and in vitro fertilisation (IVF) all require aseptic conditions.

Cleanrooms

Cleanrooms maintain positive pressure to protect the product. This is achieved by specialist airflow created by the HVAC system and room design.

They are used in many sectors, such as electronics, research and pharmaceutical manufacturing.

Containment laboratories

Containment laboratories require air pressure negative to atmosphere to stop the escape of hazardous pathogens, which is achieved by the specialist airflow created by the HVAC system and room design.

They are used in many fields, for example microbiology, forensic science, tropical disease research, immunology and vaccinology, biotechnology and veterinary medicine.

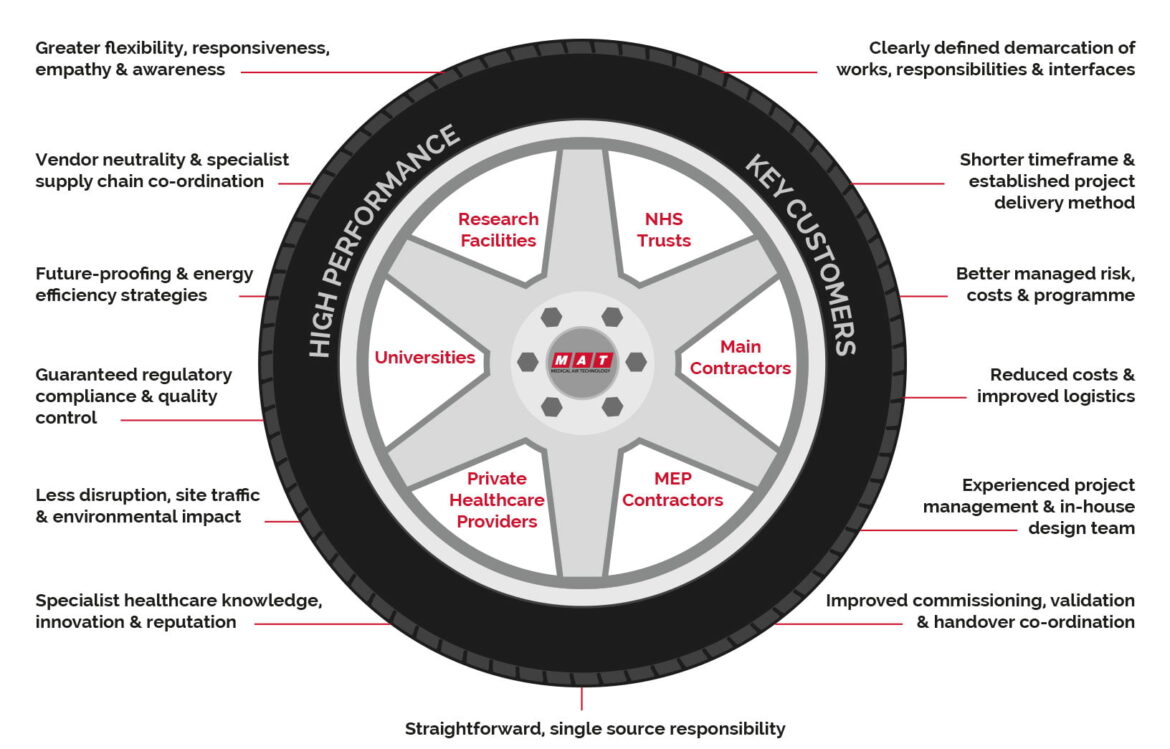

The benefits of working with a specialist contractor

Our specialist team brings its expertise to all areas of your project, from start to finish and beyond:

We manage cost, risk, programme and compliance, and make value engineering an integral part of everything we do. In addition, we are flexible, co-operative and very happy to work with your preferred products, contractors and suppliers, if required.

“On behalf of the BMI Estates Team, I would like to thank MAT for their efficient, smooth, and defect-free installation at BMI Mount Alvernia Hospital. We were very impressed.”

Martin Duggan: Head of Infrastructure Programme, BMI Healthcare