MAT delivers turnkey design-and-build modular labs at the University of Warwick

“These new labs provide world-class

facilities for research that will promote

better disease control for medicine and

for agriculture.”

Richard Napier

Deputy Head of School of Life Sciences,

University of Warwick

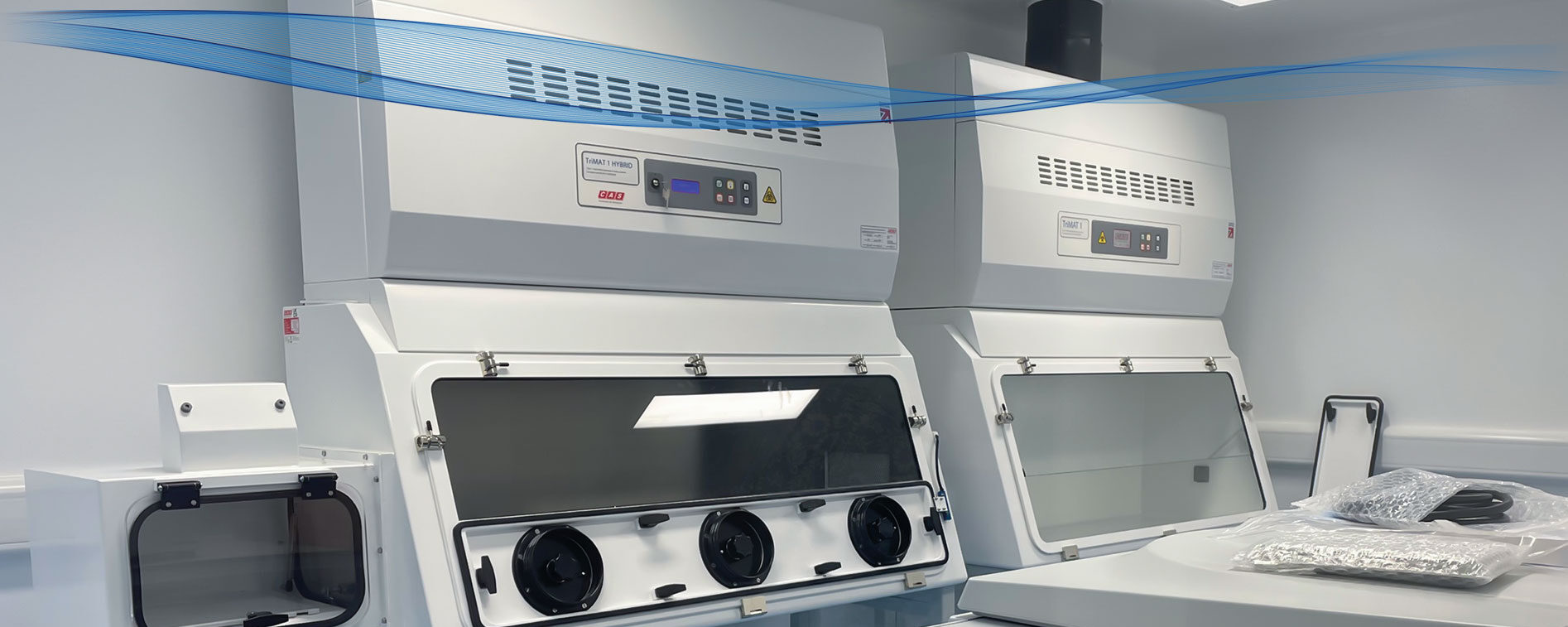

The University of Warwick is recognised as being one of the UK’s leading universities and is home to excellent facilities for experimentation and analysis. When the university decided to expand its laboratory infrastructure with three new Containment Level 3 (CL3) suites, one to be built with enhanced security measures, Medical Air Technology (MAT), which has a huge amount of experience in laboratory and cleanroom construction, was brought in to run the prestigious turnkey design-and-build project as main contractor.

The new containment labs will enable scientists to conduct cutting-edge research into infectious diseases, including those caused by airborne pathogens such as tuberculosis (TB) and COVID-19.

The university had already decided to use a modular platform for the new laboratories, as they were to be installed in a land-locked courtyard surrounded by existing live laboratories and students using the site.

MAT has worked on many modular design-and-build installations, including operating theatres and aseptic suites as well as research facilities, so was in an ideal position to drive this project forward, bringing in experienced partner and modular specialist Catfoss to deliver the shell of the new laboratories, designed to MAT’s brief.

Modular construction brings with it many benefits, such as improved sustainability and compliance, faster construction to meet tight deadlines, and the opportunity to use areas of land where traditional construction may not be appropriate or possible.

For this project, the modular laboratory modules were largely fitted-out offsite at the Catfoss factory before being transported to the university. While the fitting-out was being done, MAT was able to complete all groundworks onsite before the modules were craned into position for the final installation work.

What is Containment Level 3 (CL3)?

A CL3 laboratory is an airtight, gas-tight, leak-proof room that uses specialised airflow design to ensure biocontainment by operating under a negative pressure air regime.

This level of containment is required when handling human pathogens that may be transmitted via a number of routes including inhalation, that often have a low infectious dose to produce effects, and that can cause serious or life-threatening disease.

CL3 is the highest containment level in common use in the UK and requires certain features to be incorporated into the design to ensure appropriate containment.

Laboratory security

Making containment laboratories as secure as possible is now an essential part of their design, in accordance with the Anti-terrorism, Crime and Security Act 2001 Part 7: Security of Pathogens and Toxins. The new CL3 laboratories at the University of Warwick are a security-enhanced modular build, with all products used in the construction having been thoroughly tested and shown to provide resistance to experienced attempts at forced entry.

A specialist contractor

MAT designs, manufactures, and installs bespoke critical ventilation systems and turnkey project solutions for new build and refurbishment projects. As a specialist contractor with many years’ experience, the company is passionately committed to improving patient protection and operator and product safety in demanding clinical, research and drug production arenas. The team has extensive experience of working in live environments and fully understands the challenges around delivering a project within an operational scenario.

In addition, the company’s facilities management division, MAT FM, provides a range of competitively priced and highly effective service and maintenance packages for all core products and turnkey solutions offered by MAT or other suppliers, ensuring that equipment is maintained, serviced and validated correctly for optimum performance and efficiency.

For more information, please contact Will Evans:

Email: will.evans@medicalairtechnology.com

Tel: 0844 871 2100