Design and installation expertise

Critical ventilation for healthcare and life science settings

Medical Air Technology (MAT) designs, manufactures and installs bespoke critical ventilation systems and turnkey project solutions. We are passionately committed to improving patient protection and end-user safety in demanding clinical, research and drug production arenas.

New build, reconfiguration or refurbishment – we can bring our expertise to any project. We have extensive experience of working in live environments and understand the challenges around delivering a project within a live, operational scenario. Careful planning and considerate working ensure there is as little disruption as possible to staff and patients.

Healthcare critical ventilation

We provide specialist critical ventilation solutions for hospitals and other healthcare facilities. Critical ventilation is key in ensuring infection prevention and control, making surgery safer for patients.

Our ultraclean ventilation (UCV) canopies turn a conventional operating theatre into a UCV theatre, suitable for orthopaedic procedures. This allows hospitals to increase the range of procedures they are able to offer. They can be fitted in a new theatre suite or retrofitted as part of a reconfiguration or upgrade.

We also provide specialist ventilation solutions for first stage recovery, isolation, critical care, aseptic suites, and sterile services areas across the UK.

Life sciences specialist ventilation

Laboratory ventilation involves the supply of fresh, clean air to both displace contaminated air and dilute it to safe levels. It consists of two vital factors - air handling and filtration systems.

Our critical ventilation systems are used in higher level containment laboratories, such as those designed to Containment Level 3 and Biosafety Level 3, to maintain negative air pressure. This prevents the escape of hazardous pathogens.

We also offer positive ventilation systems for aseptic suites and cleanrooms. This creates the conditions needed to maintain positive pressure and ensure product protection.

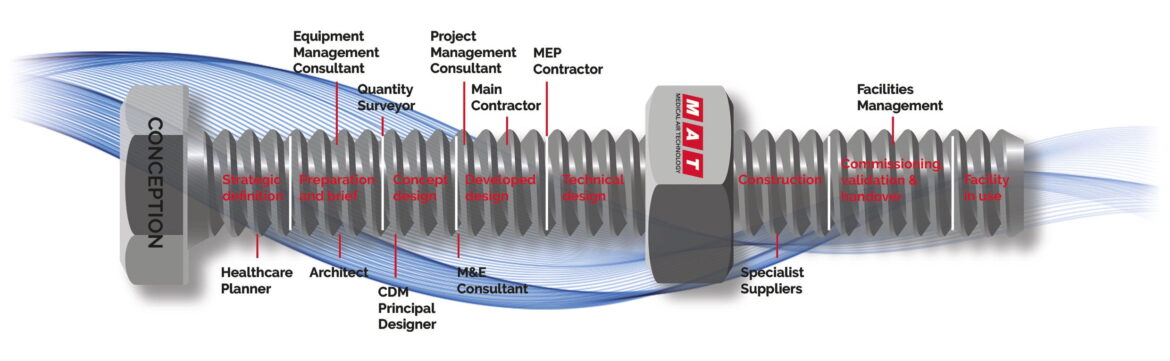

Design and project management you can trust

When you choose MAT as your specialist partner, you can be sure that you will be working with some of the best engineers, designers, and project managers in the business. We can project manage the entire process or work with the incumbent architect and design consultant.

Vendor-neutral and independent

We manage cost, risk, programme and compliance, providing all the benefits that come from working with a specialist contractor. Although we can advise on suppliers, we are completely vendor-neutral and independent, and happy to accommodate a client’s preferred supply chain, if required.

Streamlined end-user collaboration

We provide an interface between all stakeholders so that each department’s input is taken into account. This minimises the chance of stoppages and delays and ensures that everyone is in agreement around the choice of specialist equipment, room design, and fixtures and fittings.

Walsall Healthcare NHS Trust

“Following the final works within theatres 5 and 6, I just wanted to thank you and your team for all of your professional efforts to achieve completion. The refurbishment of the theatres – including the provision of new ultraclean ventilation systems – is to a high standard, provides value for money, and of course was completed before the Christmas break, as planned.

“Your efforts have brought a facility and equipment that was well beyond its normal life expectancy up to modern standards – and provided a top-class environment for patients and staff alike. Well done, and I look forward to working with the team on similar schemes.”

Colin Plant: Project Director, Walsall Healthcare NHS Trust

Streamlined design team communication

We have one of the best design teams in the business, who will work closely with the other contractors involved in the project to ensure streamlined delivery of the final installation.

Our clients

We are proud to have worked with some of the UK’s leading healthcare and research facilities. Details of our many projects can be found in our News section, which is updated regularly, or on our LinkedIn page.

“MAT secured a contract to refurbish Theatres 3 and 4 and replace both air plants at Fairfield General Hospital by competitive tendering, and a very challenging 8-week contract period was set. The scheme was completed on time, within the agreed tender sum and to a very high standard of work. The theatre management team and the consultant surgeons are delighted with the final product. I look forward to working with MAT and their supply chain subcontractors when the next opportunity arises, and I have no hesitation in recommending MAT to others.”

David Shepherd: Principal Project Manager, Pennine Acute Hospitals NHS Trust