Wansbeck General Hospital becomes the first UK hospital to install MAT ECO-FLOW STEALTH flush-to-ceiling UCV

Medical Air Technology (MAT) has completed the second phase of work on a £5.5m turnkey operating theatre refurbishment at Wansbeck General Hospital, successfully commissioning and handing over Theatres 1-4.

This landmark project is particularly exciting because two of the four theatres are the first in the country to feature MAT’s new ECO-flow Stealth, an ultraclean (UCV) screenless canopy that fits flush to the ceiling, its streamlined appearance and advanced performance very much in line with current trends in operating theatre design.

The UCV system in the ECO-flow Stealth works by drawing air to each corner of the room to control the airflow pattern and prevent entrainment. A key feature of the canopy is the use of remote fans, which enable it to achieve noise levels of just 49dBA – 53dBA, easily meeting or exceeding the reduced level recommended in the recently revised HTM 03-01 (2021).

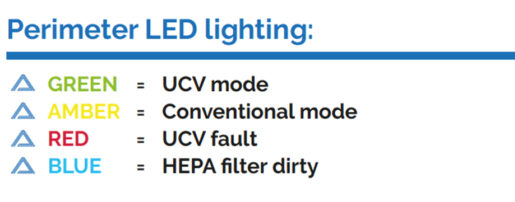

Quieter operation is just one of the benefits offered by the ECO-flow Stealth, which also has perimeter LED lighting that changes to indicate the status of the canopy. This aids ease of operation and maintenance and, most importantly, improves patient safety.

The canopy’s flush-to-ceiling design means there are zero architectural clashes with other equipment such as lights and pendants. Add to this the energy-efficient digital EC fans, cruciform lighting, and expert exponential airflow design that achieves outstanding ultraclean conditions, and it’s easy to see why MAT is so delighted with the new ECO-flow Stealth and its use at Wansbeck General Hospital.

The best operating theatres, surgical staff, and patient care

MAT completed the first phase of the work at Wansbeck General Hospital – the upgrade of Theatres 5 and 6 – in 2021. When, part way into the construction of the new theatres in phase 2, MAT offered Northumbria Healthcare NHS Foundation Trust the new ECO-flow Stealth system as an alternative to the planned screened ECO-flow UCVs, it was happy to accept, knowing the hospital would be the first in the NHS to offer surgical teams and patients the Stealth technology.

With the ECO-flow Stealth and ECO-flow screened canopies, the hospital’s theatres can now be run in both ultraclean and conventional theatre conditions, allowing for greater flexibility of use and helping the Trust to achieve its aim of increasing efficiency and minimising waiting times for elective treatment. Mr Scott Muller, Consultant Orthopaedic Surgeon and lead for the project, said that his surgical team’s jobs are made much easier by having top-of-the-range facilities to work in, and he thanked MAT for being “considerate and conscientious”.

A Specialist Contractor

MAT designs, manufactures, and installs bespoke critical ventilation systems and turnkey project solutions for new build and refurbishment projects. As a specialist contractor with many years’ experience, the company is passionately committed to improving patient protection and operator and product safety in demanding clinical, research and drug production arenas. The team has extensive experience of working in live environments and fully understands the challenges around delivering a project within an operational scenario.

In addition, the company’s facilities management division, MAT FM, provides a range of competitively priced and highly effective service and maintenance packages for all core products and turnkey solutions offered by MAT or other suppliers, ensuring that equipment is maintained, serviced and validated correctly for optimum performance and efficiency.

For more information, please contact Will Evans:

Email: will.evans@medicalairtechnology.com

Tel: 0844 871 2100